Manufacturing AI Solutions That Deliver ROI in Weeks, Not Years

Turn disconnected plants into intelligent, profitable operations with a unified manufacturing AI platform.

Why Is Intelycx the Smarter, Faster Path to Digital Transformation?

Intelycx gives manufacturers a unified, AI-driven manufacturing solution that provides manufacturing connectivity, normalizes data across plants, and delivers real-time guidance that deploys in weeks and scales with every line.

Connect Everything in Days

Unify Your Factory Floor

Intelycx quickly connects your machines and systems into one view, delivering real-time data visibility from across the factory in a matter of days through secure industrial IoT (IIoT) connectivity.

Optimize with AI

Drive Intelligent Operations

Built-in AI for manufacturing improves quality, flags issues early, and guides your teams on the floor, helping you keep output stable and waste low through continuous manufacturing optimization.

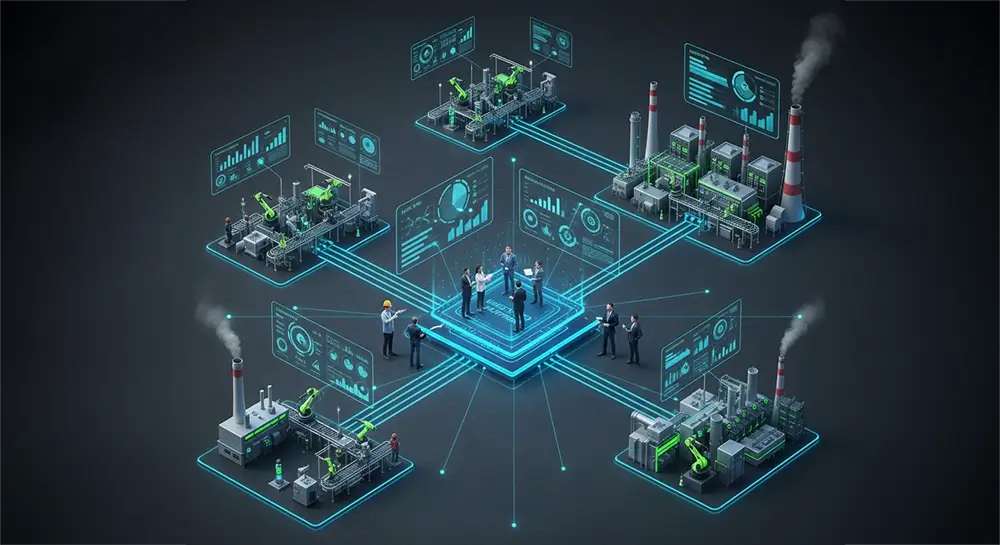

Scale with Confidence

A Platform for Industry 5.0

Intelycx grows with you, from one line to multiple plants, acting as a smart manufacturing platform for Industry 5.0 that supports fast decisions on the floor and consistent standards across your operations.

Why Do Traditional Manufacturing Operations Struggle with Profitability?

Traditional plants are under constant pressure to increase output while holding down costs, yet many still rely on disconnected systems, manual workarounds, and a shrinking pool of experts. Leaders can’t easily see what’s really happening, maintenance teams react to problems instead of preventing them, quality issues are caught late, and new hires take months to reach the level of those retiring, all of which squeezes already thin margins.

Lack of real-time visibility

Data silos

OT/IT disconnect

Reactive maintenance

Unplanned downtime

Quality variation

Scrap and rework

Dependent on experts

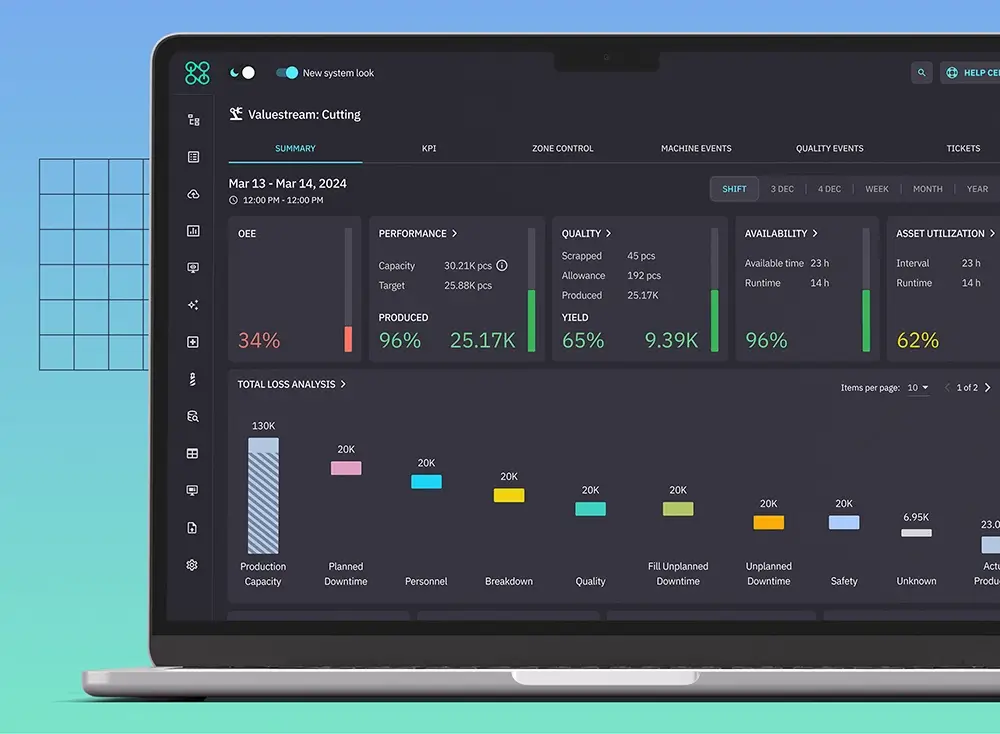

Intelycx provides leaders with real-time visibility into key KPIs, including throughput, downtime, and OEE (Overall Equipment Effectiveness), enabling them to anticipate issues and support their teams, ultimately protecting margins rather than constantly chasing problems.

What Is a Manufacturing AI Solution?

A manufacturing AI solution combines manufacturing connectivity, industrial data collection, and AI models in one platform, so leaders can see what’s happening, understand why it’s happening, and know what to do next.

These solutions go beyond static dashboards to deliver guidance that targets the biggest production losses, reduces unplanned downtime, improves OEE, and helps every role on the floor work more effectively.

The Unified Platform for Manufacturing Intelligence

Intelycx delivers a complete manufacturing intelligence platform with modular capabilities that work together seamlessly, eliminating the need for multiple disconnected systems and replacing them with enterprise manufacturing intelligence software that scales.

Real-Time Data Foundation for Connected Manufacturing

CORE serves as the central nervous system of the factory, delivering universal machine connectivity and real-time data ingestion across production assets. It integrates legacy machine integration, PLCs, sensors, and enterprise systems into a single manufacturing analytics platform powered by industrial analytics software. Manufacturers gain immediate visibility into throughput, downtime, and OEE without complex configuration or custom development.

AI-Powered Workforce and Digitized Best Practices

Aris transforms workforce productivity by digitizing tribal knowledge and embedding best practices directly into frontline workflows. The platform captures expert procedures, standard work, and corrective actions, then delivers AI-guided instructions to operators in real time. By reducing reliance on undocumented expertise, ARIS accelerates onboarding, reduces errors, and protects operational continuity as experienced workers retire.

Automated Quality Control with Computer Vision

NEXACTO applies advanced computer vision to automate quality inspection with 99%+ accuracy. By continuously analyzing products in real time, the system performs quality control automation, detecting defects, process drift, and anomalies earlier than manual inspections. Manufacturers using NEXACTO reduce defects by up to 30% while improving consistency and lowering labor costs associated with rework and scrap.

What Makes Intelycx Different from Other Manufacturing Software?

Most manufacturing software is either built for massive enterprises with long, expensive projects or sold as point solutions that never quite fit together. Intelycx combines enterprise‑grade AI with a unified, fast‑to‑deploy manufacturing AI platform that manufacturers of all sizes can implement and scale, avoiding the complexity of stitching together multiple manufacturing software tools.

Most Manufacturing Software

- Complex, multi‑year rollouts

- Separate tools for data, AI, and quality

- Heavy customization and consulting

- Designed for new equipment

Intelycx

- Deploys in weeks

- One platform for data, AI, quality

- Preconfigured modules with simple setup

- Works across new and legacy equipment

How Quickly Can We See Results with Intelycx?

Most manufacturers achieve measurable operational improvements within weeks by following a simple, proven deployment model that transforms scattered machine data into actionable insights.

Connect

Intelycx connects to new and legacy machines using secure edge computing and IIoT protocols, enabling real-time data visibility without disrupting production.

Analyze

AI models continuously analyze operational data to identify downtime risks, quality issues, and performance gaps across production, maintenance, and labor.

Act

Teams receive prescriptive alerts, predictive maintenance signals, and guided actions that drive immediate manufacturing process optimization and sustained improvement.

Trusted by Industry Leaders for Measurable Results

Real-World Results

See how a global manufacturer reduced defects and improved response times within weeks using Intelycx.

reduction in defect rates and rework costs

quicker issue resolution

faster onboarding for new hires

faster response to bottlenecks

Learn More About the Future of Manufacturing

Stay informed on the latest manufacturing trends, AI breakthroughs, and real-world success stories that are reshaping the industry.

Ready to See the Future of Manufacturing?

Schedule a live demo to see how Intelycx reduces downtime, improves quality, and delivers measurable ROI through AI-driven manufacturing solutions.