The United States manufacturing sector is facing a historic paradox. A “Manufacturing Renaissance,” fueled by aggressive reshoring and advanced technology, is colliding with a demographic “Silver Tsunami” that is draining the industry of its most valuable asset: institutional knowledge. As factories become smarter, the workforce is shrinking, creating a knowledge gap that threatens to derail this momentum.

This article provides a definitive answer to “What is Industry 4.0 manufacturing?” by framing it not as a technological upgrade, but as the strategic solution to this critical workforce crisis. We will dissect the core technologies, explore the business imperatives that competitors overlook, and provide a practical roadmap for implementation. By leveraging Industry 4.0, manufacturers can decouple operational excellence from individual tenure, turning the workforce crisis into a generational opportunity for competitive advantage.

Why is Manufacturing Facing a Paradox of Progress and People?

We are in the midst of a manufacturing supercycle. Spurred by the supply chain vulnerabilities exposed during the pandemic and a strategic geopolitical realignment, reshoring has surged. The Reshoring Initiative reports that U.S. companies and foreign investors have announced nearly 2 million jobs since 2010, with a remarkable spike of 244,000 jobs in 2024 alone, primarily in high-tech sectors like EV batteries and semiconductors [1].

Simultaneously, this technological leap is colliding with a demographic cliff. The industry is facing a “Silver Tsunami.” The Alliance for Lifetime Income reports that over 30 million “Peak Boomers” will turn 65 between 2024 and 2029 [2]. As they retire, they take decades of unwritten, “tribal” knowledge with them—the intuition that a specific machine vibration signals a bearing failure, a nuance no manual can capture.

This creates the Great Manufacturing Paradox: we have the most advanced factories in history, but we are rapidly losing the very people who know how to run them. The National Association of Manufacturers (NAM) projects a potential shortfall of 1.9 million manufacturing employees by 2033 due to this skills gap [3]. The question is no longer if this will impact your business, but when.

What is Industry 4.0 Manufacturing, and Why Does It Matter Now?

Industry 4.0 is the fourth industrial revolution, representing the digital transformation of manufacturing. It is a paradigm shift where physical production processes are deeply intertwined with digital technology, creating a single, intelligent system of interconnected operations. It is not just about automation; it is about creating smart factories that can sense, predict, and interact with the physical world to make autonomous, real-time decisions.

To understand its significance, we must view it in historical context:

| Industrial Revolution | Era | Core Technology | Impact on Manufacturing |

| First (1.0) | Late 18th Century | Steam & Water Power | Mechanization of production |

| Second (2.0) | Late 19th Century | Electricity & Assembly Line | Mass production and scale |

| Third (3.0) | Late 20th Century | Computers & Automation | Digitization and initial automation |

| Fourth (4.0) | Present | Cyber-Physical Systems & AI | Autonomous, data-driven, interconnected factories |

In semantic terms, Industry 4.0 can be understood through a simple framework:

- Entity: The Manufacturing Process

- Attribute: Level of Intelligence & Connectivity

- Value: Fully Autonomous and Interconnected

This means that every asset, process, and worker is connected, sharing data that is analyzed by artificial intelligence to optimize the entire value chain, from supply chain logistics to shop floor operations and quality control.

What Are the Core Technologies That Power a Smart Factory?

Industry 4.0 is not a single technology but a confluence of nine foundational pillars that, when integrated, create the smart factory. While many competitors list these technologies, they fail to connect them to the strategic imperative of solving the workforce paradox. Here, we dissect each pillar and its specific role in bridging the knowledge gap.

1. The Industrial Internet of Things (IIoT)

The IIoT is the central nervous system of the smart factory. It consists of a network of sensors, actuators, and other devices embedded in industrial machinery that collect and transmit real-time data about the machine’s health, performance, and environment. This data can include temperature, pressure, vibration, energy consumption, and output.

- Gap Solution: The IIoT captures the machine’s “feel” that a retiring expert used to sense. That subtle change in vibration or temperature that once only existed as intuition in a senior technician’s mind is now captured as objective, quantifiable data. This allows the system to detect anomalies and trends that a new hire would never notice, effectively digitizing decades of experience.

2. Artificial Intelligence (AI) and Machine Learning (ML)

If IIoT is the nervous system, AI and ML represent the brain. These algorithms process the immense data streams from IIoT sensors to identify patterns, predict outcomes, and prescribe actions. This includes predictive maintenance (forecasting equipment failure before it happens), anomaly detection (identifying deviations from normal operating parameters), and process optimization (recommending adjustments to improve yield or quality).

- Gap Solution: AI acts as a “virtual senior technician,” constantly monitoring operations and flagging issues. It can analyze thousands of variables simultaneously, identifying complex correlations that would be impossible for a human to spot. For a junior technician, it’s like having a seasoned expert looking over their shoulder, providing data-driven guidance and preventing costly mistakes.

3. Cloud Computing

Cloud platforms provide the scalable, on-demand computing power and storage necessary to handle the massive datasets generated by a smart factory. This eliminates the need for manufacturers to invest in and maintain expensive on-premise data centers, making advanced analytics accessible to companies of all sizes.

- Gap Solution: The cloud democratizes access to high-powered analytics and institutional knowledge. A solution developed at a plant in Ohio can be instantly available to a team in Texas. This breaks down the geographic silos of expertise and ensures that best practices are disseminated across the entire organization, not just held by a few.

4. Big Data and Analytics

This pillar refers to the practice of analyzing large, complex datasets (“big data”) to uncover hidden patterns, correlations, and other insights. In a manufacturing context, this means analyzing historical production data, quality data, and maintenance logs to understand the root causes of systemic issues.

- Gap Solution: Big data analytics can codify decades of production history. By analyzing years of data, a manufacturer can identify the precise conditions that lead to a specific type of defect, knowledge that was previously held only in the collective memory of its most experienced employees. This transforms tribal knowledge into a permanent, searchable corporate asset.

5. Cybersecurity

As factories become more connected, they also become more vulnerable to cyberattacks. A robust cybersecurity framework is essential to protect sensitive operational data, intellectual property, and the physical safety of the plant. This includes network security, endpoint protection, and identity and access management.

- Gap Solution: As institutional knowledge is digitized and becomes a core asset, protecting it is paramount. A strong cybersecurity posture ensures that this newly created “digital brain” is safe from corruption, theft, or ransomware attacks that could cripple operations.

6. Digital Twins

A digital twin is a virtual replica of a physical asset, process, or even an entire factory. It is fed with real-time data from IIoT sensors, allowing it to mirror the state of its physical counterpart. This enables manufacturers to run simulations, test new process parameters, and train operators in a virtual environment without disrupting physical production.

- Gap Solution: A digital twin provides a safe sandbox for learning. A new engineer can experiment with process changes on the digital twin, observing the virtual consequences of their actions without the risk of causing real-world downtime, scrap, or safety incidents. It accelerates the learning curve by allowing for trial and error at zero cost.

7. Additive Manufacturing (3D Printing)

Additive manufacturing enables the creation of complex, three-dimensional objects directly from a digital file. In an industrial context, this is used for rapid prototyping, creating custom jigs and fixtures, and even producing on-demand spare parts for machinery.

- Gap Solution: An experienced engineer can design a custom tool or a replacement part for a legacy machine and save the design file digitally. Years later, long after that engineer has retired, any technician can access that file and print the exact part needed, preserving a critical piece of operational knowledge.

8. Augmented Reality (AR)

AR technology overlays digital information—such as step-by-step work instructions, real-time performance data, or expert video guidance—onto a user’s view of the physical world, typically through a tablet or smart glasses.

- Gap Solution: AR gives a junior technician the “eyes of an expert.” When performing a complex changeover or repair, the AR system can guide them through each step, highlighting the correct parts, displaying the required torque specifications, and even connecting them to a remote expert for live assistance. This dramatically reduces the time-to-competency and minimizes human error.

9. Autonomous Robots

These are not the caged robots of the past. Modern autonomous robots can work safely alongside humans, performing tasks that are repetitive, physically demanding, or require a high degree of precision. They can transport materials, perform quality inspections, and even carry out complex assembly tasks.

- Gap Solution: By automating the mundane and physically strenuous tasks, autonomous robots free up human workers to focus on higher-value activities like problem-solving, process improvement, and quality control. This elevates the role of the manufacturing worker, making the job more engaging and less physically taxing, which can help attract and retain new talent.

Why Should Your Business Adopt Industry 4.0?

Adopting Industry 4.0 is not a technology project; it is a strategic business imperative. It addresses the critical gaps that competitors ignore, moving beyond simple productivity to create lasting organizational resilience.

- Imperative 1: From Data Overload to Actionable Intelligence. Most companies are drowning in data but starving for wisdom. The challenge is not data collection, but utilization. Industry 4.0 platforms are designed to filter the signal from the noise, automatically detecting critical deviations and prescribing actions, turning data into decisions.

- Imperative 2: Decoupling Expertise from Individuals. The core challenge of the “Silver Tsunami” is that knowledge is mortal. Industry 4.0 makes it immortal. By capturing process data, maintenance logs, and expert insights in a unified system, you create a corporate brain that outlives any single employee.

- Imperative 3: Building Resilience in the Face of Disruption. The pandemic proved that rigid supply chains break. A fully connected Industry 4.0 ecosystem provides end-to-end visibility, allowing manufacturers to anticipate disruptions, pivot production dynamically, and build a truly resilient operation.

- Imperative 4: Securing a Lasting Competitive Advantage. Competitors often treat Industry 4.0 as table-stakes. This is a mistake. True competitive advantage comes from using these tools to solve the workforce crisis more effectively than your rivals, enabling you to scale operations, maintain quality, and innovate faster even as the labor market tightens.

How Does Industry 4.0 Work in Practice?

Let’s move beyond theory. How does this work in practice? Consider this scenario.

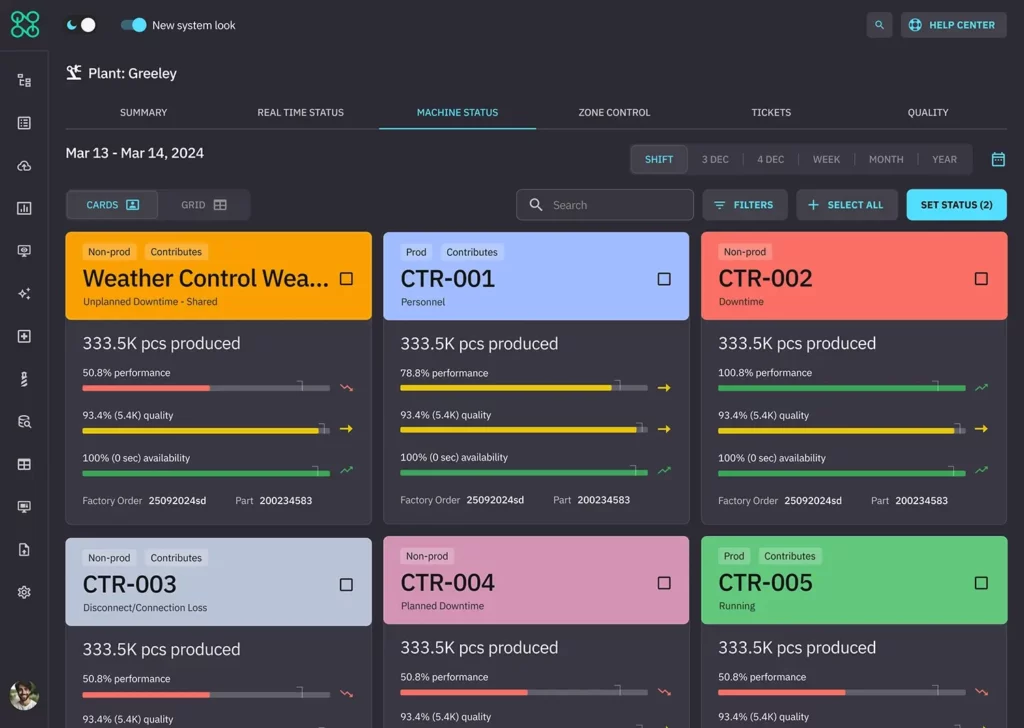

The Scenario: Apex Dynamics, a Tier-1 automotive supplier. User: Marcus, the Plant Manager. Problem: The critical Stamping Line #4 has seen its Overall Equipment Effectiveness (OEE) inexplicably drop for three straight shifts, putting a key customer delivery at risk.

The Old Way (Without Industry 4.0): Marcus spends hours manually pulling reports from three different systems. He tasks a junior engineer, Sarah, to interview the operators. The answer is a mix of opinions: “the die felt slow,” “the feeder seemed off.” They are flying blind.

The Industry 4.0 Way (with an Industrial Intelligence Platform):

- 2:05 PM: Querying the Data. Marcus opens his tablet and asks the platform: “Show me the OEE breakdown for Line 4 over the last 72 hours, compared to the month-to-date average.”

- Platform Response: “Line 4 OEE is 68%, down from the 82% average. The drop is driven by a 15% loss in Availability due to micro-stoppages and one major downtime event coded ‘Feeder Jam’.”

- 2:07 PM: Leveraging Internal Knowledge. Marcus recalls a veteran technician, Bob, who retired last year, knew everything about that feeder. He asks: “Search all shift notes and maintenance logs from Bob related to ‘Feeder Jams’ on the Komatsu press.”

- Platform Response: “Found a shift log from Bob (Oct 2023): ‘Feeder jams on the Komatsu often happen when the coil stock lubrication is too heavy. It causes the optical sensors to slip. Solution: Reduce lubrication flow by 10% and clean the optical eye.’”

- 2:10 PM: Taking Action. Marcus dispatches Sarah, the junior technician. Using an AR-enabled tablet, the system overlays the exact location of the lubrication valve and the optical sensor, guiding her through the 2-minute fix. The line restarts.

The Result: In less than 10 minutes, a problem that could have halted production for a full day was diagnosed and solved. The platform didn’t just provide data; it provided institutional memory and actionable guidance. Sarah has now learned a critical piece of tribal knowledge, and her successful interaction reinforces the solution within the system for the next person.

What Are the Biggest Challenges to Implementing Industry 4.0?

While the promise of Industry 4.0 is immense, the path to implementation is not without its challenges. Acknowledging and planning for these hurdles is the first step toward a successful transformation. Many competitors gloss over these realities, but a practical approach requires addressing them head-on.

| Challenge | Description | Strategic Solution |

| 1. Legacy System Integration | Most factories are a heterogeneous mix of old and new equipment with proprietary protocols. Integrating these disparate systems into a unified data platform is a primary technical hurdle. | Adopt a platform with a robust library of connectors and an edge layer that can translate legacy protocols. Start with critical assets and expand incrementally, rather than attempting a “big bang” integration. |

| 2. Data Overload and Quality | The sheer volume of data from IIoT can be overwhelming. Without a clear strategy, this can lead to “data paralysis.” Furthermore, if the data is inaccurate or incomplete, any resulting analytics will be flawed. | Implement a “data governance” framework from the outset. Define what data is critical to collect, establish standards for data quality, and use AI-powered tools to automatically cleanse and contextualize data at the source. |

| 3. High Initial Investment Costs | The upfront cost of sensors, software, and infrastructure can be a significant barrier, especially for small and medium-sized manufacturers (SMEs). | Shift from a CapEx to an OpEx model by leveraging cloud computing and Software-as-a-Service (SaaS) platforms. Start with a pilot project focused on a high-value problem (e.g., a bottleneck machine) to demonstrate a rapid ROI and build the business case for further investment. |

| 4. Cybersecurity Risks | Every new connection point is a potential vector for a cyberattack. A security breach in a smart factory can lead to production shutdowns, intellectual property theft, or even physical safety hazards. | Implement a “defense-in-depth” cybersecurity strategy that includes network segmentation, endpoint protection, regular vulnerability assessments, and ongoing employee training. Security cannot be an afterthought; it must be designed into the architecture from day one. |

| 5. Skills Gap and Workforce Training | The existing workforce may lack the digital skills necessary to operate and maintain a smart factory. The shortage of data scientists, AI specialists, and robotics engineers is a major constraint on adoption. | Invest in a continuous upskilling and reskilling program. Use AR and digital twin technologies to accelerate training and empower existing workers with new digital tools. Partner with local universities and technical colleges to build a pipeline of future talent. |

| 6. Organizational Resistance to Change | The human element is often the biggest challenge. A new technology initiative can be met with fear, skepticism, or inertia from a workforce accustomed to established routines. | Implement a comprehensive change management program. Clearly communicate the “why” behind the transformation, involve employees from all levels in the design and implementation process, and celebrate early wins to build momentum and demonstrate the value of the new approach. |

How is Industry 4.0 Being Used in Different Industries?

Industry 4.0 is not a one-size-fits-all solution. Its application varies significantly across different manufacturing sectors, each with its own unique challenges and opportunities.

Automotive

In the hyper-competitive automotive sector, Industry 4.0 is crucial for managing complex supply chains and enabling mass customization. Digital twins are used to simulate entire production lines, allowing engineers to optimize for the introduction of new EV models without physical retooling. AI-powered computer vision systems inspect for microscopic defects in paint and body work at a speed and accuracy no human can match. At a major Tier-1 supplier, the implementation of an IIoT platform to monitor stamping presses reduced unplanned downtime by 30% and improved OEE by 12% within six months.

Pharmaceuticals and Life Sciences

For pharmaceutical manufacturers, compliance and quality are paramount. Industry 4.0 enables a move towards “Pharma 4.0,” where the entire production process is digitally tracked and verified in real time. Electronic Batch Records (EBRs) automatically capture data from production equipment, eliminating manual data entry errors and ensuring data integrity (ALCOA+). This enables Review-by-Exception (RbE), where QA teams only need to review deviations from the validated process, reducing batch release times from weeks to days, or even hours.

Electronics and Semiconductors

In the high-precision world of semiconductor manufacturing, yields are everything. The slightest environmental variation can ruin an entire batch of wafers. IIoT sensors monitor thousands of parameters in the cleanroom—from temperature and humidity to airborne particle counts—in real time. AI algorithms analyze this data to predict how these variations will impact yield, allowing engineers to make proactive adjustments. A leading semiconductor manufacturer used machine learning to optimize its etching process, resulting in a 5% increase in yield, which translated to hundreds of millions of dollars in annual savings.

Consumer Packaged Goods (CPG)

The CPG industry is characterized by high volume and low margins, making operational efficiency a key driver of profitability. Autonomous robots are used to automate packaging and palletizing, while AI-powered demand forecasting helps to optimize production schedules and reduce inventory costs. A major beverage company implemented a digital twin of its supply chain, which allowed it to simulate the impact of different promotional strategies and optimize its distribution network, leading to a 15% reduction in logistics costs.

How Can You Implement Industry 4.0 in Your Factory?

Transitioning to a smart factory is a journey, not a destination. It does not require a risky, all-or-nothing “rip and replace” of your existing infrastructure. A strategic, phased approach is the key to building momentum, demonstrating value, and ensuring long-term success.

Phase 1: Foundational – Connect and Visualize (Months 1-3)

The goal of this phase is to establish a single source of truth. You cannot manage what you cannot see.

- Action: Identify a critical bottleneck or a high-value production line to serve as the pilot project. Connect your most critical assets using IIoT gateways. Focus on capturing key metrics like OEE (Overall Equipment Effectiveness), downtime reasons, and production counts.

- The Intelycx Role: We deploy our edge devices and pre-built connectors to establish connectivity with your existing equipment, regardless of age or protocol. Our platform begins to collect and visualize this data in real-time dashboards.

- Outcome: You move from manual, after-the-fact data collection to real-time, automated visibility. For the first time, you have a live, undisputed view of what is happening on your factory floor.

Phase 2: Intelligence – Analyze and Predict (Months 4-9)

With a foundation of reliable data, the next step is to turn that data into intelligence.

- Action: Begin to apply AI and machine learning algorithms to your data. Implement predictive maintenance models for your critical assets. Use anomaly detection to identify deviations from normal operating parameters in real time.

- The Intelycx Role: Our platform’s AI engine analyzes your historical and real-time data to build predictive models. The system starts to forecast potential failures and alert your team before they happen. We help you configure automated alerts and workflows based on these insights.

- Outcome: You shift from a reactive maintenance culture (“fix it when it breaks”) to a proactive one (“fix it before it breaks”). Unplanned downtime begins to decrease, and asset reliability improves.

Phase 3: Integration – Digitize and Guide (Months 10-18)

This phase focuses on digitizing human processes and integrating them with the machine data.

- Action: Digitize your standard operating procedures (SOPs), quality checklists, and maintenance work instructions. Implement AR-guided workflows for complex tasks. Begin to capture the tribal knowledge of your senior experts through guided interviews and log their insights into the system.

- The Intelycx Role: We help you build a comprehensive knowledge base within the platform. Our AR tools allow you to create guided workflows that connect directly to the real-time data from your machines. The ARIS Gen AI co-pilot starts to learn from your internal documents and expert input.

- Outcome: You begin to close the skills gap. New hires can perform complex tasks with fewer errors and less supervision. The knowledge of your most experienced employees is captured and democratized, becoming a permanent asset.

Phase 4: Autonomy – Optimize and Scale (Months 19+)

This is the final stage, where the smart factory becomes a truly autonomous, self-optimizing system.

- Action: Deploy autonomous robots for material handling and quality inspection. Allow the AI to make closed-loop process adjustments in real time. Scale the solution from your pilot line to the entire factory, and then across your enterprise.

- The Intelycx Role: We help you scale the platform and integrate it with your broader enterprise systems (ERP, SCM). The AI models are continuously refined, and the system provides enterprise-wide analytics for strategic decision-making.

- Outcome: Your factory operates at a new level of efficiency and agility. Continuous improvement is no longer a periodic event but an automated, ongoing process. You have built a resilient, learning organization that is prepared for the challenges of the future.

What is the Real ROI of an Industry 4.0 Investment?

An investment in Industry 4.0 is not an expense; it is a strategic investment in profitability and competitive advantage. The business case is built on tangible, quantifiable returns across multiple dimensions of the manufacturing operation.

| ROI Driver | How It’s Achieved | Typical Financial Impact |

| 1. Increased Throughput | Reducing unplanned downtime through predictive maintenance. Optimizing production schedules with AI. | 5-20% increase in OEE. For a production line generating $10M in annual revenue, a 10% OEE improvement translates to $1M in additional revenue with minimal additional cost. |

| 2. Reduced Maintenance Costs | Shifting from reactive/preventive maintenance to predictive, condition-based maintenance. Fewer emergency repairs and less unnecessary scheduled maintenance. | 10-40% reduction in maintenance costs. If a plant spends $2M annually on maintenance, this can result in $200k – $800k in annual savings. |

| 3. Improved Quality | Using AI-powered computer vision to detect defects in real time. Analyzing process data to identify the root causes of quality issues. | 10-50% reduction in scrap and rework. For a manufacturer with a 5% scrap rate on $20M of production, a 20% reduction in scrap saves $200k annually. |

| 4. Reduced Labor Costs | Automating manual data collection and reporting. Using AR to reduce training time and improve first-time fix rates. Automating repetitive tasks with robots. | 10-30% improvement in workforce productivity. Reducing the onboarding time for a new technician from 6 months to 3 months can save $20k – $40k per hire in training and lost productivity costs. |

| 5. Optimized Energy Consumption | Monitoring energy usage at the machine level in real time and identifying opportunities for optimization. | 5-15% reduction in energy costs. For a facility with a $1M annual energy bill, this can deliver $50k – $150k in annual savings. |

| 6. Reduced Working Capital | Improving supply chain visibility to reduce inventory levels. Accelerating batch release times in regulated industries. | 10-30% reduction in inventory holding costs. Reducing inventory by $5M can free up significant cash flow and reduce annual holding costs by $500k – $1.5M. |

The Payback Period: While the total investment can vary, many Industry 4.0 pilot projects demonstrate a payback period of just 6-18 months, with the subsequent factory-wide rollout delivering exponential returns.

What’s Next? From Industry 4.0 to Industry 5.0

Even as many manufacturers are just beginning their Industry 4.0 journey, the next paradigm is already emerging: Industry 5.0. While Industry 4.0 is focused on connecting machines and automating processes for efficiency, Industry 5.0 brings the human element back to the center of the equation, emphasizing a deeper, more collaborative partnership between humans and smart systems.

- Human-Centricity: Industry 5.0 prioritizes human well-being, safety, and creativity. It aims to augment human capabilities, not replace them. This involves using collaborative robots (cobots) to assist workers with physically demanding or dangerous tasks, and AI systems that act as creative partners in problem-solving.

- Sustainability: There is a much stronger emphasis on sustainability and the circular economy. Industry 5.0 technologies will be used to optimize energy consumption, minimize waste, and design products and processes that are environmentally sustainable from cradle to grave.

- Resilience: Building on the lessons of recent global disruptions, Industry 5.0 aims to create supply chains and production systems that are not just efficient, but also highly resilient and adaptable. This involves creating distributed manufacturing networks and using AI to anticipate and respond to geopolitical, environmental, and economic shocks.

Conclusion: Why is Now the Time to Act?

The convergence of the manufacturing renaissance and the workforce crisis has created a unique window of opportunity. The question is no longer if you should invest in Industry 4.0, but how quickly you can deploy it to protect your most valuable asset: your operational knowledge.

Sticking to traditional methods is a choice to let your competitive advantage walk out the door. Industry 4.0 is the bridge across the talent chasm. It is the mechanism to capture the irreplaceable wisdom of your experienced workforce and empower the next generation to perform at a level that once took decades to achieve.

The technology exists. The pain points are acute. The only variable remaining is leadership courage. Manufacturers must embrace Industry 4.0 now to turn the “Silver Tsunami” from a looming disaster into a digital transformation opportunity.

References

[1] Reshoring Initiative. “2024 Reshoring Report.” Reshoring Initiative Data Reports, reshoringinstitute.org/data-reports/.

[2] Alliance for Lifetime Income. “The Peak 65 Generation.” Alliance for Lifetime Income Research, protectedincome.org/peak-65.

[3] Deloitte and The Manufacturing Institute. “The Manufacturing Talent Dilemma.” Deloitte Insights, deloitte.com/us/en/insights/industry/manufacturing/manufacturing-industry-diversity.html.

[4] European Commission. “Industry 5.0: Towards a sustainable, human-centric and resilient European industry.” European Commission, research-and-innovation.ec.europa.eu/knowledge-publications-tools-and-data/publications/all-publications/industry-50-towards-sustainable-human-centric-and-resilient-european-industry_en.

[5] National Institute of Standards and Technology (NIST). “Cybersecurity Framework Version 2.0 Manufacturing Profile.” NIST, csrc.nist.gov/pubs/ir/8183/r2/ipd.

[6] Devlin, Jacob, et al. “BERT: Pre-training of Deep Bidirectional Transformers for Language Understanding.” arXiv, 2018, arxiv.org/abs/1810.04805.

[7] McKinsey & Company. “Capturing the true value of Industry 4.0.” McKinsey, www.mckinsey.com/capabilities/operations/our-insights/capturing-the-true-value-of-industry-four-point-zero.

[8] IBM. “What is Industry 4.0?” IBM, www.ibm.com/think/topics/industry-4-0.

[9] SAP. “What is Industry 4.0?” SAP, www.sap.com/products/scm/industry-4-0/what-is-industry-4-0.html.

[10] World Economic Forum. “The Future of Jobs Report 2023.” World Economic Forum, www.weforum.org/reports/the-future-of-jobs-report-2023/.

[11] PwC. “Digital Factories 2020: Shaping the future of manufacturing.” PwC, www.pwc.com/gx/en/industries/industrial-manufacturing/publications/digital-factories-2020.html.

[12] Boston Consulting Group. “The Factory of the Future.” BCG, www.bcg.com/capabilities/operations/factory-of-the-future.

[13] Gartner. “Top Strategic Technology Trends for 2024.” Gartner, www.gartner.com/en/articles/top-strategic-technology-trends-for-2024.

[14] Siemens. “Digital Twin: The Ultimate Guide.” Siemens, www.siemens.com/global/en/products/software/digital-twin.html.

[15] Rockwell Automation. “The Connected Enterprise.” Rockwell Automation, www.rockwellautomation.com/en-us/capabilities/connected-enterprise.html.

[16] PTC. “What is Industry 4.0?” PTC, www.ptc.com/en/solutions/digital-manufacturing/industry-4-0.

[17] Cisco. “What is Industry 4.0?” Cisco, www.cisco.com/site/us/en/learn/topics/networking/what-is-industry-4-0.html.

[18] Oracle. “What is Industry 4.0?” Oracle, www.oracle.com/scm/manufacturing/what-is-manufacturing/what-is-industry-4-0/.

[19] Epicor. “What is Industry 4.0?” Epicor, www.epicor.com/en-us/blog/technology-and-data/what-is-industry-4-0/.

[20] ABI Research. “Industry 4.0 Technologies & Examples.” ABI Research, www.abiresearch.com/blog/industry-4-0-technologies-examples.