The term “Industrial IoT” gets thrown around a lot, especially in conversations about smart factories, Industry 4.0, and now Industry 5.0. But for most manufacturing leaders, the real question is simpler: what is IIoT, and how does it actually improve uptime, quality, and profitability on the plant floor?

This article breaks down what Industrial IoT is, how IoT in manufacturing actually works, and what to look for in an IIoT platform if you want real results, not another stalled “digital transformation” project.

What Is the Industrial Internet of Things (IIoT)?

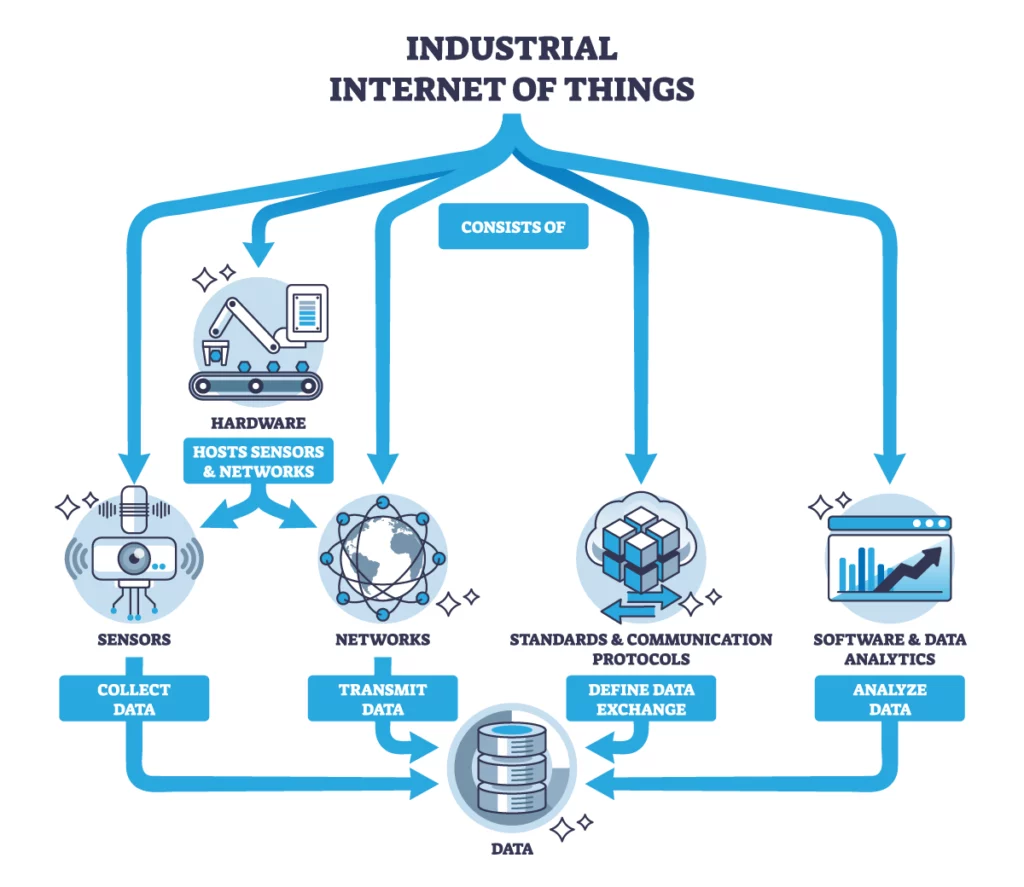

The Industrial Internet of Things (IIoT) is the use of connected devices, sensors, and software to collect and analyze data from industrial equipment in real time. In manufacturing, IIoT connects machines, lines, and systems so teams can see what’s happening, why it’s happening, and what to do next to improve performance.

In practice, IIoT in manufacturing means:

- Machines, PLCs, and sensors continuously sending data (speeds, temperatures, faults, cycles) to a central system.

- An IIoT platform normalizing that data so it’s consistent across legacy and modern assets.

- Industrial IoT software turning that data into real-time dashboards, alerts, and analytics.

When done right, the internet of things in manufacturing moves you from lagging, spreadsheet-based reporting to live, plant-wide visibility.

What Is the Difference Between IoT and Industrial IoT?

IoT (Internet of Things) is a broad term that covers consumer and commercial devices, such as smart thermostats, fitness trackers, or connected appliances. Industrial IoT, or IIoT, focuses specifically on industrial environments like factories, warehouses, and plants.

| IoT | IIoT | |

|---|---|---|

| Environment | Homes, offices, retail. | Harsh industrial settings with vibration, heat, dust, and strict uptime requirements. |

| Devices | Consumer sensors, cameras, appliances. | PLCs, CNC machines, robots, inspection cameras, industrial sensors, and IIoT gateways. |

| Goals | Comfort, convenience, energy savings. | Reduced unplanned downtime, higher OEE, better quality, and safer, more efficient operations. |

Industrial IoT platforms, therefore, must handle noisy data, legacy protocols, and mission-critical uptime in a way consumer IoT software never has to. This is why generic consumer IoT tools rarely fit the demands of IoT in manufacturing.

How Is IoT Used in Manufacturing?

IoT in manufacturing shows up across the entire production lifecycle, from raw materials to finished goods. Common internet of things industrial applications include:

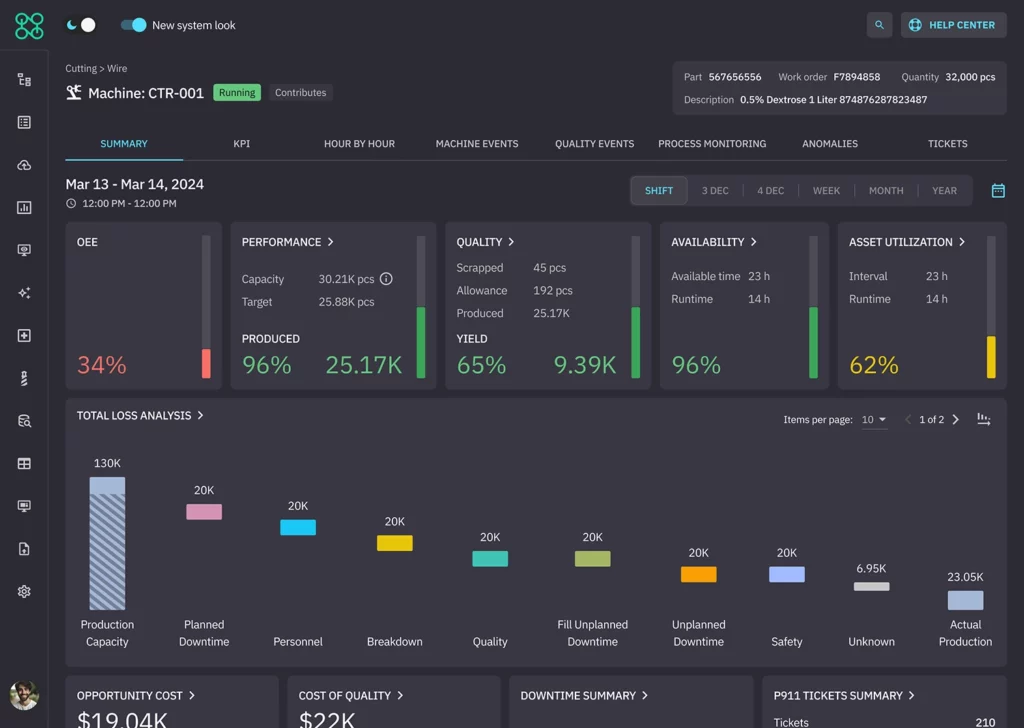

Real-Time Machine Monitoring

Industrial IoT devices stream data like cycle counts, temperatures, currents, and vibration into a central IIoT platform. Operations can see machine status, OEE, and bottlenecks in real time instead of waiting for next-day reports. This is one of the most common entry points for the internet of things in manufacturing.

Predictive Maintenance

Industrial IoT data feeds predictive models that spot patterns before a failure. For example, increased vibration on a spindle or rising motor temperature can automatically trigger a maintenance work order before unplanned downtime hits.

Quality Control and Traceability

IIoT solutions connect vision systems, torque tools, and inspection stations so every part carries a full digital history. When defects appear, teams can trace issues back to specific batches, shifts, or equipment conditions.

Energy and Utility Monitoring

IoT in factories captures energy usage by machine, line, or plant. Leaders use this insight to cut waste, shift loads, and reduce energy costs without guessing.

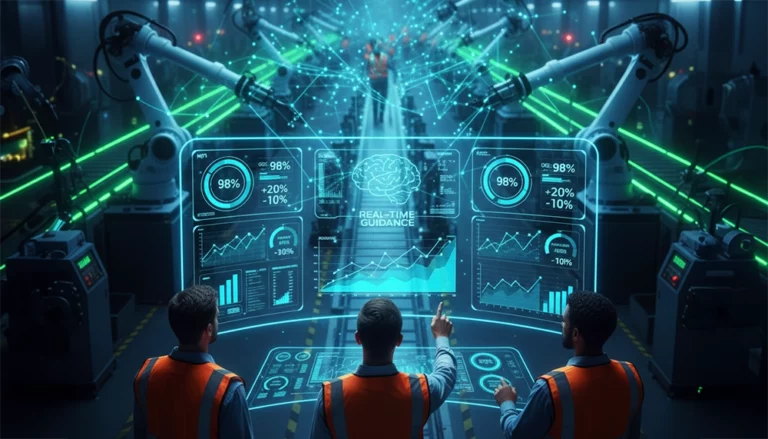

Workforce Support and Safety

Industrial IoT systems can feed data into operator dashboards or AI copilots. Operators see live KPIs, guided instructions, and alerts instead of walking the floor chasing information.

These are not theoretical IIoT projects. They are practical use cases manufacturers deploy today to get measurable ROI from IoT in manufacturing.

What Are Industrial IoT Devices?

Industrial IoT devices are the hardware components that collect and transmit data in industrial environments. A typical industrial IoT system may include:

- Sensors – For temperature, pressure, vibration, current, flow, and more.

- PLCs and Machine Controllers – Existing control hardware that exposes machine state, alarms, and counters.

- Connected Cameras – Used for automated visual inspection and quality control.

- IIoT Gateways – Edge devices that connect legacy machines to an IIoT platform, translate industrial protocols, and securely send data to the cloud.

- Industrial PCs and Edge Nodes – For local processing, buffering, and analytics at the edge.

For example, a manufacturing IoT setup might combine vibration sensors on motors, PLC data from packaging lines, and cameras on inspection stations, all routed through an IIoT gateway into an industrial internet of things platform. This combination of devices is what makes IoT in manufacturing able to monitor entire lines in real time.

What Is an Industrial IoT Platform?

An industrial IoT platform (or IIoT platform) is the software layer that connects all your industrial IoT devices, ingests their data, normalizes it, and makes it available as real-time insights.

A robust industrial IoT platform should:

Connect to Any Equipment

Support legacy machine integration, modern PLCs, robots, and industrial IoT hardware using common OT protocols.

Standardize Data

Turn inconsistent tags and signals into a unified data model, so OEE, downtime, and throughput look the same across lines and plants.

Provide Real-Time Monitoring

Offer live dashboards, alerts, and trends for production, quality, and maintenance teams.

Integrate with Enterprise Systems

Feed clean industrial IoT data into ERP, MES, CMMS, and analytics tools without custom one-off integrations for every project.

Enable AI and Advanced Analytics

Serve as the trusted data foundation for AI-driven manufacturing use cases like predictive maintenance, automated visual inspection, and AI-guided troubleshooting.Think of the IIoT platform as the central nervous system that makes internet of things in manufacturing solutions usable at scale instead of isolated pilots. Platforms like Intelycx CORE are designed to be this foundation, unifying machine data across legacy and modern assets and delivering real-time visibility in weeks.

What Problems Does IIoT Solve in Manufacturing?

Manufacturing IoT and IIoT solutions directly address long-standing operational issues that erode margins:

Lack of Real-Time Visibility

Without internet of things manufacturing data, many plants rely on manual logs and delayed reports. IIoT platforms replace this with real-time factory monitoring so leaders can see issues as they develop.

Unplanned Downtime

Industrial IoT data lets teams track conditions that lead to failures, such as overheating drives, erratic currents, and frequent minor stops. Predictive maintenance software built on IIoT data helps reduce surprise breakdowns.

Data Silos and OT/IT Disconnect

It is common to see separate systems for machines, MES, ERP, and quality. IIoT in industry unifies machine data and feeds it into a single industrial IoT system, bridging operational technology (OT) and information technology (IT).

Inconsistent Quality and Scrap

By combining process parameters, line speed, and inspection data, internet of things industrial applications help pinpoint the exact conditions that drive defects and rework.

Slow, Manual Decision-Making

When engineers and supervisors spend hours pulling reports from different systems, decisions lag. IIoT data and industrial IoT software compress that cycle into minutes.

What Are Examples of Industrial Internet of Things in Action?

Here are a few practical examples of industrial internet solutions on modern factory floors that show IoT in manufacturing at work:

Stamping Line OEE Improvement

A metal parts manufacturer connects presses, conveyors, and inspection cameras into a manufacturing IoT platform. Operators see live OEE, top downtime reasons, and defect rates per shift. Over months, they use this data to cut changeover times and reduce unplanned stops.

Automotive Paint Shop Quality Control

Industrial IoT devices capture oven temperatures, conveyor speeds, and humidity, while vision systems inspect for paint defects. The IIoT platform correlates defects with process variables, enabling targeted fixes instead of generic troubleshooting.

Food and Beverage Packaging Line Reliability

Vibration and current sensors stream data into an IIoT gateway. Predictive models detect bearing wear and misalignment patterns before a major failure. Maintenance can schedule repairs in planned windows instead of during peak production.

These examples of Industrial Internet of Things use cases share one pattern: a connected data foundation plus focused applications for uptime, quality, and throughput.

How Is IoT Used in Factories Day-to-Day?

At a day-to-day level, IoT in factories changes how teams work:

- Operators see clear, real-time dashboards instead of guessing whether a line is ahead or behind target.

- Maintenance teams receive alerts when conditions cross thresholds, not after a machine is already down.

- Quality teams have continuous visibility into defect rates and process parameters, not just end-of-shift summaries.

- Leaders get consolidated plant and multi-plant views, replacing disconnected spreadsheets and manual reports.

When internet of things and manufacturing come together, the outcome is not just more data. It is more predictable operations and fewer “fire drill” days.

What Should You Look for in an Industrial IoT Solution?

Not all industrial IoT platforms and services are created equal. When evaluating IIoT solutions for manufacturing, focus on capabilities that actually move the needle:

Universal Connectivity

The IIoT platform should connect to legacy machines and modern equipment without expensive rip-and-replace projects. Look for support for common industrial protocols and a clear story around IIoT gateways and device integration.

Fast Time to Value

A strong industrial IoT system connects lines and delivers initial insights in weeks, not quarters. Ask for concrete timelines and examples of IIoT implementation in similar plants.

Scalable Architecture

Check that the internet of things platform handles higher data volumes, more lines, and additional sites without a full redesign. This includes secure industrial IoT networks, edge processing, and robust cloud or hybrid options.

Ease of Use

Your teams should not need a data science background to interpret industrial IoT data. Look for clear, role-based dashboards and easy-to-interpret KPIs that work for operators, engineers, and executives.

Integration with Existing Systems

Industrial IoT platforms should push data into your MES, ERP, CMMS, or analytics stack. This avoids creating another silo and maximizes the value of your existing investments.

Path to AI and Advanced Applications

The best IIoT platforms act as a foundation for AI-driven manufacturing, supporting computer vision, AI-guided troubleshooting, and intelligent worker support as your maturity grows.

How Does Industrial IoT Support Industry 4.0 and Industry 5.0?

IIoT in manufacturing started as a core pillar of Industry 4.0: connect devices, collect data, and automate where possible. As the landscape moves toward Industry 5.0, the focus expands:

- Industry 4.0 – Emphasizes connectivity, automation, and smart systems.

- Industry 5.0 – Adds a stronger human-centric focus, where AI and connected systems act as copilots to the workforce.

Industrial IIoT provides the real-time manufacturing data that feeds AI assistants, visual inspection systems, and intelligent work instructions. Instead of replacing people, industrial internet of things platforms augment operators, engineers, and leaders with live, contextual guidance.

Is Industrial IoT Worth the Investment?

For most manufacturers, the more relevant question is: what is the cost of not having real-time visibility and connected systems?

Without an industrial IoT platform, plants typically face:

- Higher unplanned downtime due to reactive maintenance.

- Lower OEE from unmeasured minor stops and slow cycles.

- Higher scrap and rework costs from late detection of process drift.

- Slower decisions, because data is scattered across systems or locked in spreadsheets.

By contrast, manufacturers that deploy practical IIoT projects, starting with machine connectivity and then expanding into analytics and AI, see:

- More predictable operations.

- Faster, data-backed decision-making.

- A scalable foundation for continuous improvement across sites.

Where to Start with IIoT in Manufacturing

If you are exploring IoT for manufacturing, you do not need to boil the ocean on day one. A practical path looks like this:

- Start with Connectivity

Connect key machines and lines to an industrial IoT platform and begin streaming real-time data.

- Establish Core KPIs

Standardize metrics like OEE, availability, downtime reasons, and scrap across the connected assets.

- Address One High-Impact Use Case

For example, unplanned downtime on a bottleneck line or quality issues in a critical process.

- Scale to Additional Lines and Sites

Once the initial IIoT project proves value, expand the same approach and add advanced use cases like predictive maintenance or automated visual inspection.

This staged approach ensures IIoT stays focused on measurable business outcomes instead of becoming a never-ending pilot.

Ready to Move Forward with Industrial IoT?

Whether you are just getting started with IoT in manufacturing or you have already taken the first steps toward a connected factory, the next challenge is turning data into reliable, day-to-day decisions.

Intelycx is purpose-built for this reality. Our unified manufacturing AI platform connects legacy and modern machines, normalizes your data, and delivers real-time, AI-driven insights that help teams reduce downtime, improve quality, and boost OEE in weeks, rather than waiting years.

If you are exploring how to build or scale your Industrial IoT strategy, you can learn more about our solutions and approach at intelycx.com.