AI-Powered Visual Inspection for Quality Control

Reduce Defects, Streamline Production, and Achieve Unmatched Accuracy

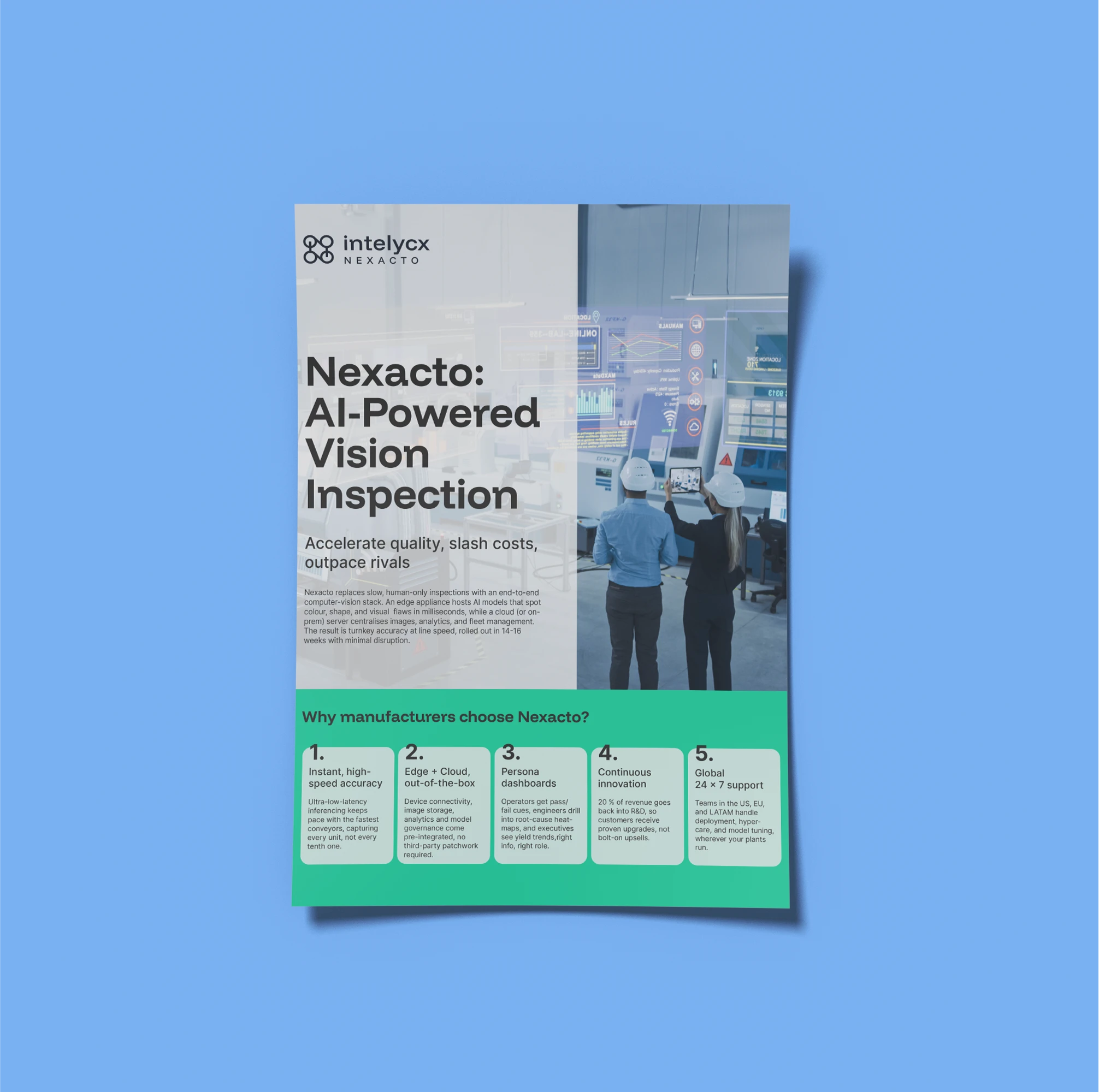

Collaborative AI-Powered Quality Assurance

Nexacto is an AI-powered computer vision system automating visual inspections to quickly detect defects, reduce human error, and minimize rework costs. It frees your workforce for higher-value tasks, boosting efficiency and quality.

With real-time alerts and adaptive learning, Nexacto integrates effortlessly into your existing workflows. Upcoming capabilities include verifying safety gear usage and ensuring lines are clear between batches, further enhancing product consistency and workplace safety.

Common Quality Control

Pitfalls in Modern Manufacturing

Manual Inspections

& Human Error

Relying on human inspection alone often leads to oversights—especially when team members are fatigued or rushed. This can result in production slowdowns, variable quality, and increased scrap rates.

Delayed Detection

of Defects

Without real-time monitoring, issues may only surface after production runs are complete, causing high rework costs and missed deadlines. Traditional systems lack the agility to spot defects or anomalies as they happen.

Scaling Quality Assurance Across Sites

As facilities expand or new product lines launch, maintaining consistent, rigorous quality checks can be challenging. Fragmented quality systems can hamper operations and risk brand reputation if defects slip through.

How Nexacto Delivers

Collaborative Precision

Real-Time Defect Detection

With super‑low latency vision processing, Nexacto flags surface flaws, colour shifts, and dimensional deviations the instant they appear, keeping pace with the fastest production lines.

Adaptive Learning

As Nexacto processes more data, it refines inspection criteria automatically, adapting to new product designs or subtle material variations.

Cost‑Saving Automation

Nexacto takes over routine visual checks, removing labour bottlenecks and delivering the primary ROI consistent, 24/7 inspection without human fatigue

Seamless Integration

Compatible with your existing lines, Nexacto requires minimal reconfiguration. You can start small on a single line and scale up without disrupting ongoing processes.

Driving Better Outcomes

for People & Production

Lower Defect Rates & Rework Costs

Nexacto's automated visual inspection replaces manual checks, reducing human inspection costs and cutting defect rates by up to 30%. By detecting issues instantly, manufacturers save on materials and labor, consistently delivering high-quality products while safeguarding their brand reputation.

Faster Production Cycles

With real-time feedback loops, production lines can adjust mid-run, preventing widespread issues. Many clients report shortened lead times and tighter adherence to delivery commitments after deploying Nexacto.

Enhanced Traceability & Compliance

Nexacto automatically logs inspection results, creating a digital audit trail for compliance requirements. This robust traceability reduces administrative work and demonstrates regulatory readiness across multiple markets.

Practical Scenarios:

How Nexacto Excels in Real-World QC

One Example: Automotive Parts Supplier

A mid-sized auto parts manufacturer struggled with tight production windows and variable skill levels among QA staff. Shifts often missed minor paint imperfections or subtle dimensional errors, driving up rework costs.

By deploying Nexacto, each assembly line gained immediate defect alerts and an AI partner that could adapt as production specs evolved. Within weeks, the supplier saw a significant drop in product returns and higher confidence across its QA teams.

Insights & Updates

Stay informed on the latest manufacturing trends, AI breakthroughs, and real-world success stories that are reshaping the industry.

Elevate Quality with Intelycx NEXACTO

Ready to minimize defects and strengthen your bottom line? Integrate Intelycx NEXACTO for automated, AI-driven visual inspection that works seamlessly alongside other Intelycx CORE solutions.

To place an order or discuss your needs, reach out to our team.